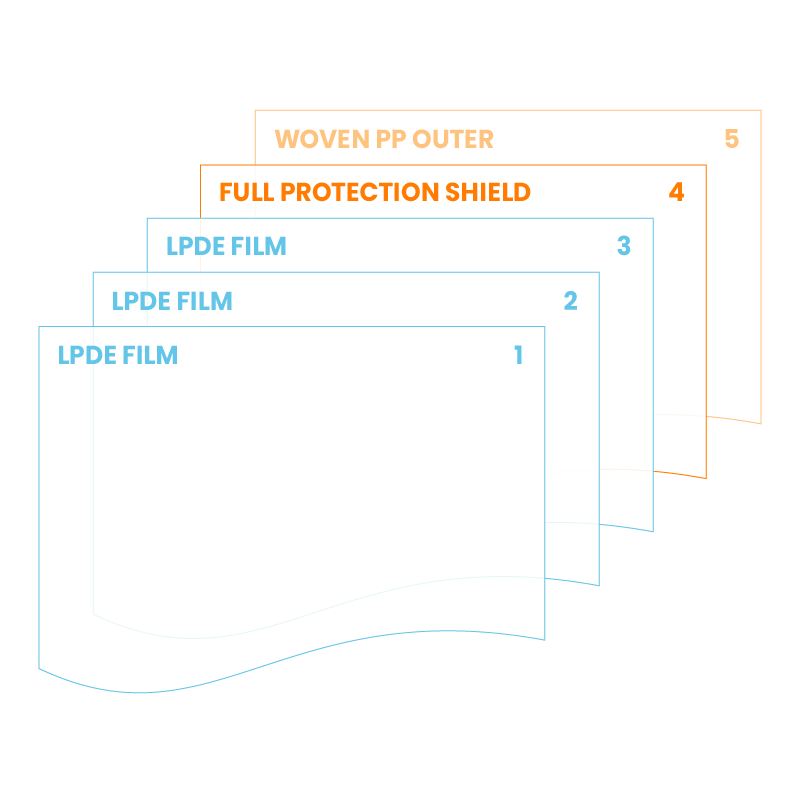

Specially designed to substitute the single layer flexitanks for your high quality industrial oils which are sensible to humidity absorption and which tend to permeate through the standard LDPE films (“sweating effect”).

The FPS Multilayer flexitank also substitutes the alu foil flexitanks for wine transports. The alu foil is very unreliable (rips open during transport) and is not recyclable. The FPS film is 100%recyclable and 100% reliable as it is a thermoform plastic. Excelent lab tests for naphtalene permeation (available on request).

| MECHANICAL PROPERTIES PE FILM | TYPICAL VALUES* | TEST METHOD |

|---|---|---|

| Tensile strength | MD ≥ 26.0 N-mm2 TD ≥ 28.0 N-mm2 |

ASTM D882 ASTM D882 |

| Elongation at Break | MD > 600% TD > 650% |

ASTM D882 ASTM D882 |

| Tear Resistance | MD ≥ 0,088 N/µm TD ≥ 0,088 N/µm |

ASTM 1004 ASTM 1004 |

| Impact strength (film total) | ≥2250g | ASTM D1709 |

| MECHANICAL PROPERTIES WOVEN | TYPICAL VALUES* | TEST METHOD |

|---|---|---|

| Tensile strength | MD ≥ 1400 N/50 mm TD ≥ 1400 N/50 mm |

ASTM D4595 ASTM D4595 |

| Elongation at Break | MD ≥ 15% TD ≥ 15% |

ASTM D4595 ASTM D4595 |

| Stitch strength | ≥ 500 N/50 mm | ASTM 1D4595 |

From product innovation and multilayer design to circular practices and certified quality, our two catalogues offer a complete view of what makes Trust Flexitanks a benchmark in the industry.